Natural stone, the building material for the success of the Construction turnaround

Sustainable construction is a key issue worldwide, as the construction and building industry is responsible for around 38% of globalCO2 emissions. The way we construct buildings today is neither resource-efficient nor climate-friendly. In order to reduce the ecological footprint in the construction sector, it is therefore essential to bring natural building materials back into the focus of architecture.

Natural stone has been used as a building material for thousands of years to create durable structures. However, in the last century, the age of seemingly infinite fossil fuels, natural stone was replaced by energy-intensive, artificial building materials and is therefore no longer used for load-bearing purposes, but mainly for "decorative" purposes. However, the potential of natural stone is not utilised in this way. Rather, as a load-bearing building material, it is a real alternative to the CO2-intensive, artificial materials currently used and is therefore ideal for the necessary decarbonisation of the construction industry.

Facts about production

Low energy consumption

As a ready-to-use raw material, natural stone is usually found close to the surface in our earth's crust and does not have to be produced using energy-intensive, artificial or even chemical processes. It simply has to be extracted from the earth and cut to size.

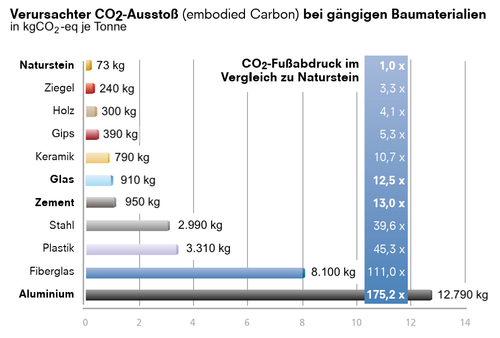

Low CO2 emissions

Natural stone lies ready for use in the earth's crust, which is why very little energy is required for the entire manufacturing process. For this reason, only very small amounts ofCO2 are emitted.

No waste

Side products generated during production and rock that cannot be used for natural stone production are not waste, but are processed into gravel or filling material, for example. Unusable material is returned to the natural cycle.

Low water consumption

Water is only used as a coolant when cutting the rock. This is recycled and reused in the cycle so that the consumption of fresh water is very low.

Model building for the new Maria Ward schools in Bamberg

Here, concrete is completely replaced by a composite masonry made of natural stone and bricks in the outer walls; architect: H2M Architekten + Stadtplaner

Stone pavilion

Teaching and research project of the Junior Professorship Solid Building Constructions, Technical University Dortmund Jun.Prof.Arch. Anne Hangebruch, student design: Ieva Saudagaite; in cooperation with Bamberger Natursteinwerk Hermann Graser GmbH

Facts about natural stone

Natural stone is robust and durable

Suitable natural stone is frost-resistant and has a lifetime of several centuries to thousands of years.

Natural stone has a high load-bearing capacity

Natural stone has a very high compressive strength and is therefore ideal as a load-bearing building material. In addition, thin and heavy-duty prefabricated parts for beams, ceilings or bridges can be produced using steel tensioning elements.

Natural stone is environmentally friendly and contains no harmful substances

The natural building material natural stone does not contain any harmful substances. Natural stone can therefore even be used in food areas.

Natural stone is not flammable

Natural stone is non-flammable and corresponds to construction class A in accordance with DIN 4102. No harmful substances are released even in the event of fire.

Natural stone has a large thermal storage mass

Buildings with load-bearing structures made of natural stone react thermally inert and thus ensure a pleasant indoor and urban climate.

Natural stone is reusable

Elements made of natural stone can be reused as often as required without energy-intensive treatment processes. Natural stone does not fatigue and can be easily cleaned and repaired if necessary.

Natural stone is not waste, even at the end of its life

If no equivalent use can be found for the natural stone at the end of the building's life, it can be processed into gravel and filling material.

Natural stone emits no CO2 at the end of its life

Unlike many other building materials, natural stone does not emit CO2 at the end of its life.

Natural stone is available in sufficient quantities

Regional natural stone has characterised our villages, communities and towns for centuries. The resources still exist today. Stone quarrying was often discontinued in the last century due to a lack of demand.

Land consumption is low

The stone resources are usually over 10 metres thick, sometimes even over 100 metres, so that in relation to other building materials the land consumption in our landscape is very low.

Natural stone is constantly being created anew

Natural stone is a permanently naturally occurring raw material that is constantly being renewed in the rock cycle. People do not realise this, but it becomes visible during volcanic eruptions, for example.

Quarries increase biodiversity

Quarries are special habitats with high biodiversity even during the extraction phases. Rare plant and animal species find a habitat here that is rarely found in our cultural landscape.

Short transport routes

When using regional natural stone, transport routes are short and CO2 emissions are low.

Compliance with all environmental, labour, safety and social standards

Of course all environmental, labour, safety and social standards are adhered to when quarrying and processing regional natural stone.

Low costs

Natural stone shows its economic advantages through its long lifetime and reusability. Even from a short-term perspective, natural stone would be one of the most favourable building materials if all building materials had to take into account the actual costs of causing and storing CO2.

Opportunities

Decarbonisation of the construction industry

Natural stone has great potential for the energy-related construction turnaround due to the low energy required for its extraction and processing, its outstanding characteristics and the quantities available.

In addition, the construction turnaround can be achieved more quickly and efficiently by utilising natural building materials than through the costly transformation of individual energy-intensive, artificial building materials.

Natural stone is suitable for hybrid constructions

Thanks to its high load-bearing capacity and fire behaviour, natural stone is also suitable for use with many other natural, near-natural or renewable building materials.

By using each material according to its optimal characteristics, constructions for the future can be created.

Integration of planners, industry and trade

Architects and planners, as well as all companies involved in construction, can use natural stone as a building material in the same way as artificially produced stones, building materials or prefabricated elements.